How we custom steel windows and doors

Every project that we produce is unique and made entirely by hand. Because quality, durability and a finish are our absolute absolute priority, every collaboration is as structured as possible.

Do you roughly know what your metal interior items or steel joinery may look like? Then you certainly can deliver us a picture, a sketch, some dimensions and the desired options. Or do you prefer to work with our online configuration tool to design your interior joinery?

Because we attach great importance to a personal approach, you and/or your architect are more than welcome in our offices in Sint-Martens-Latem and Westmalle. There we can go through all the possibilities for your custom-made steel windows and doors in detail and immediately look at some samples and tangible examples.

For outdoor applications and larger projects, we prefer to come and have a look at the site first, and already take approximate measurements. In Belgium, this site visit is of course free of charge and without any obligation.

Formulating a guide price on the spot? We prefer not to do that. After our first consultation or site visit, we immediately draw up a correct and extremely detailed price offer that includes all the options and points of interest. This way, you will never be faced with any surprises.

After approval of the offer, we will arrive on site for a precise measurement. It is preferable that you are present, because this allows us to go through and explain all preferences, options and technical specifics in detail. After that, we start working with our high-tech laser equipment. With point measurements every 2 cm, we get an accurate picture of the opening. We can also use our high-tech 3D laser in complex rooms. It accurately maps each point and all unevenness millimetre-precise and also creates a complete 3D visualisation.

Attention!

For the measurement of custom-made steel windows and doors, it is important that the doorways and floors are already fully finished. This is the only way we can guarantee correct custom production and seamless installation.

After the measurement, we process all the figures in a technical drawing. We make a technical drawing and a 3D drawing of each part and of the whole. This enables us to produce all the components smoothly and faultlessly. We also save these technical drawings for later use. This way, we no longer have to come to the site to repair a broken glass pane. This saves you and us a lot of unnecessary costs and loss of time.

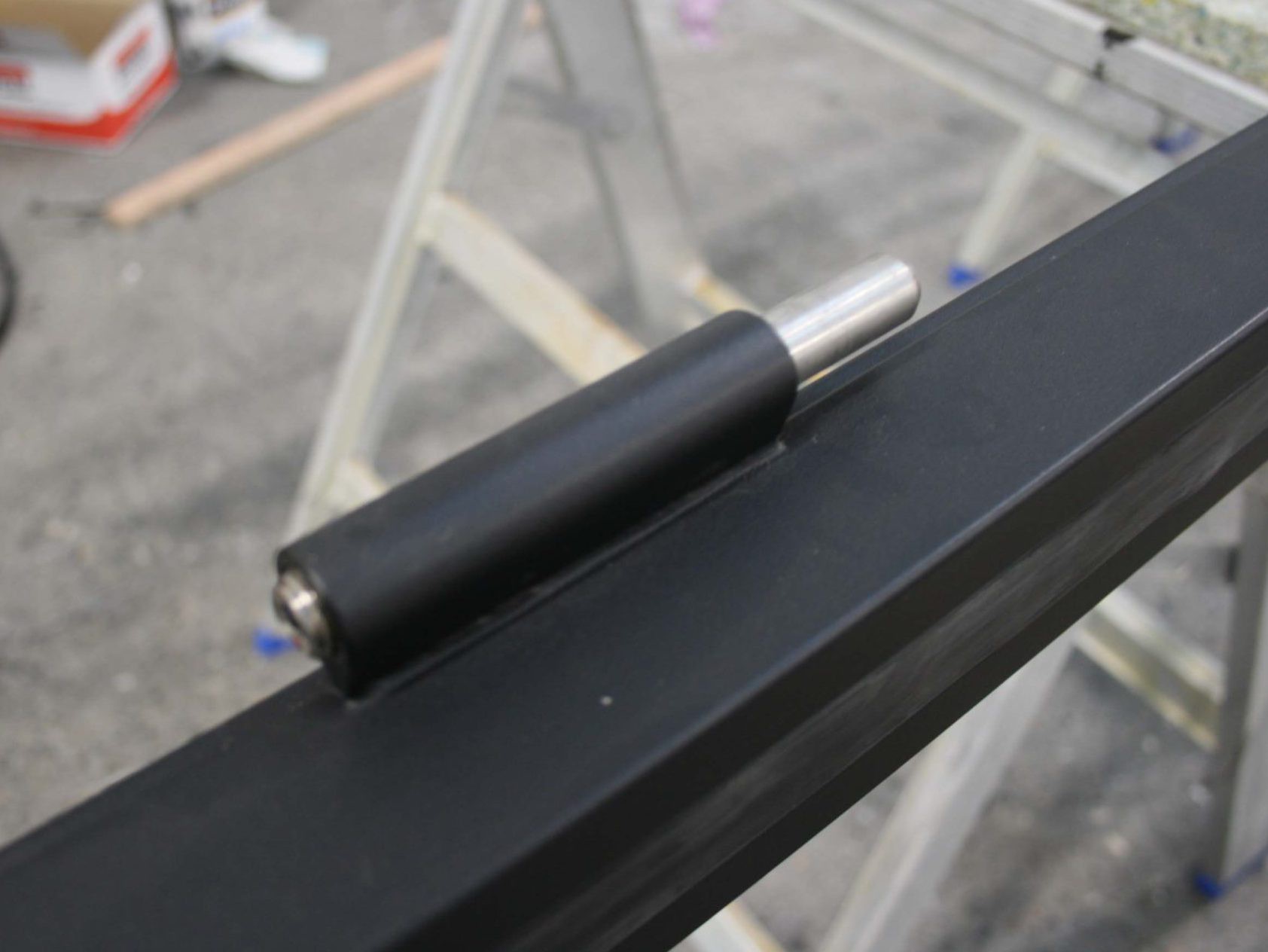

Manual welding

We bend, turn and mill the steel profiles according to plan. We then clamp the profiles onto professional welding tables to prevent curvature. Our experienced TIG welders weld all components together here. Also hinges, because at Feral they are not just screwed in a hurry, are also welded tightly. After an internal quality control of the welding work and of the conformity with the technical drawing, we clean the welds so that we have smooth profiles.

Sandblasting

We don't believe in rushing the work by treating profiles chemically. Burrs, unevenness and the grease layer on the profiles are removed using the traditional sandblasting technique. The blasting grit is also reusable, which makes this approach much more environmentally friendly. After sandblasting, the steel surface is completely clean and slightly porous, allowing the powder coating to adhere better.

Powder coating

We do not wet paint our profiles. With our powder coating technique, we create a much neater and more scratch-resistant result. The profiles are covered with electrically charged metal paint to ensure ideal adhesion and 100% coverage without spikes. An effective technique that also benefits the environment.

After powder coating, we make the profiles impact-resistant, water- and dirt-repellent and corrosion-resistant by heating them. Thanks to our professional ovens, we also save valuable drying times.

Placement of the glass

With our preferred sealing method, each glass plate is perfectly cut to size. We then place these with the greatest care and completely by hand in the profiles. Each profile side is carefully and manually sealed with the modern Soudal Tradition putty. We let each side of the custom steel windows and doors dry for at least 48 hours before we seal the other side.

The glass plate is then fixed into the sealant to avoid the risk of cold bridges and the formation of condensation and mould. The relatively flexible seal also absorbs most of the shocks and torsional forces, which significantly reduces the risk of glass breakage. If glass does break, it can be replaced relatively easily thanks to this mastic method, without having to replace the entire glass pane.

The traditional and artisanal mastic technique is our specialty. Only in the case of large glass panes that have to be assembled on site, will we use glazing beads that we can spray in the desired colour beforehand.

Before the finished product leaves our workshop, all parts are thoroughly inspected again. At Feral, we simply don't compromise on quality and finish!

The transport, installation and possible repairs afterwards? These too are carried out entirely under our own management. We keep the entire process under our own management, from concept to after-service. Without the intervention of third parties or subcontractors.